Analysis on the ARPA-E Conformable Natural Gas Tank

In May of 2011, the average price of gasoline neared $4.00 a gallon and remained over $3.50 for some time. This caused high prices at the pump, stifling the American economy. In response to this problem, ARPA-E launched the Methane Opportunities for Vehicular Energy or MOVE program to take advantage of America's abundant natural gas resources and infrastructure. One challenge facing natural gas vehicles is that the gas tanks are typically cylindrical. A cylinder does not fill all the available space due to losses in the corners. Space in a vehicle comes at a premium, and nobody was going to switch to natural gas if the trunk was eliminated from their vehicle. Grocery room comes at a premium.

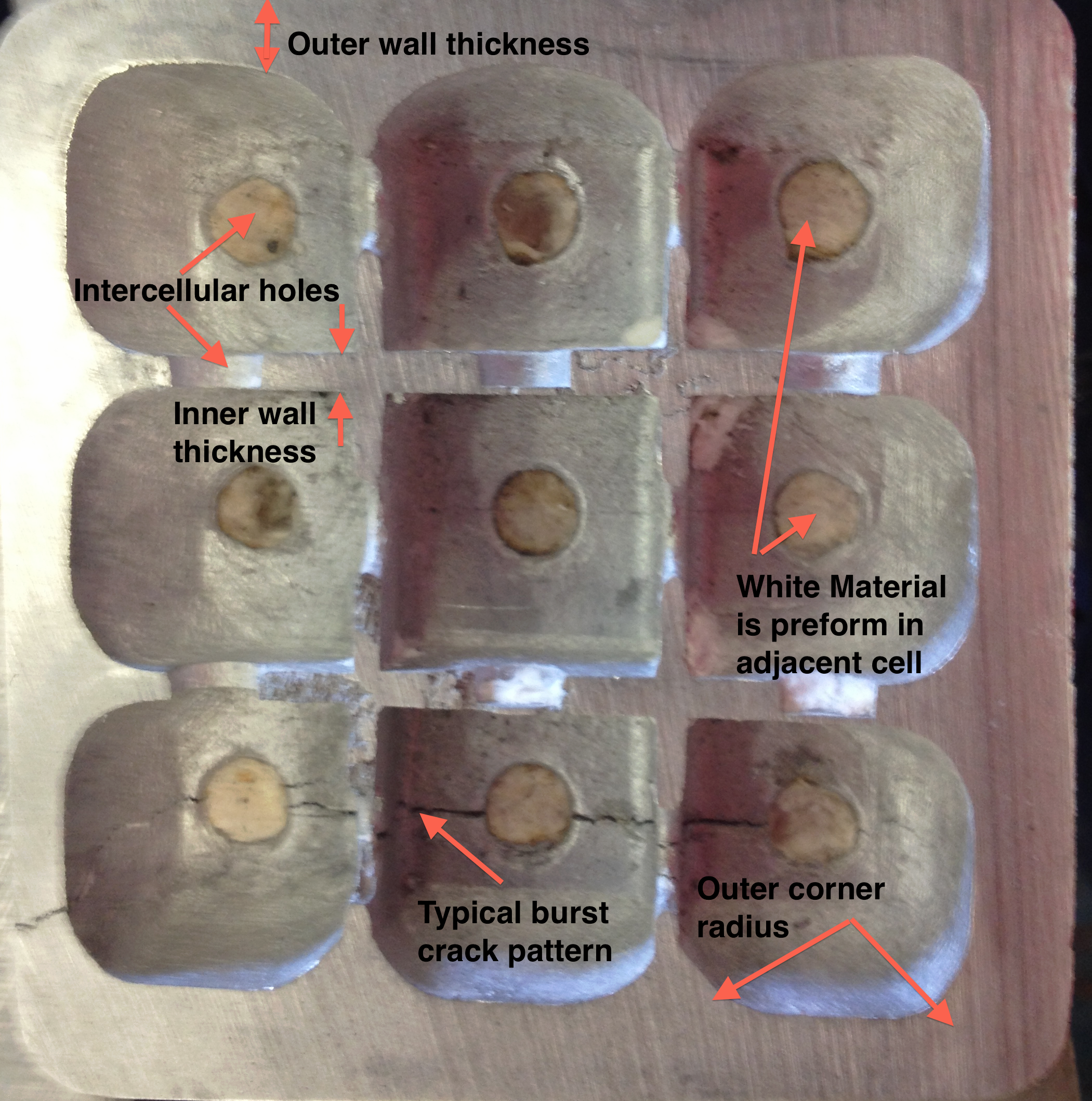

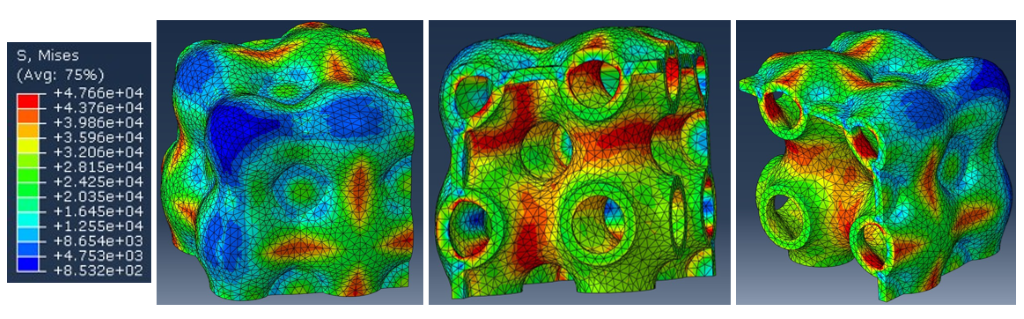

ARPA-E contracted REL Inc. (technology division now spun off to Loukus Tech) to build a conformable natural gas tank that would allow for much higher packing density of natural gas in vehicles. During the ARPA contract, the government point of contact, Dr. Dane Boysen, happened upon the Schwarz-P surface at a math exploration event for children (as I recall). He suggested the P-surface to all companies working the contract as an inner structure to the tank.

The P-surface allowed for a much lower stress design to be built, as it involves none of these fatal holes.

The price of a gallon of gas fell precipitously in late 2014, reaching $2.07 in February of 2015, in large part due to the hydraulic fracturing technology in oil drilling. At these new prices, it was difficult to see natural gas competing with oil, and interest in the project as an onboard vehicle solution waned. The technology is now being developed for static storage and as a heat exchanger. If you are interested in the tank, contact Loukus Tech.

If you need help with your difficult project and are wondering if simulation can help, talk to us here.